Electric Turbocharging

Once an exotic technology, turbocharging has become mainstream. Back a few decades ago, turbochargers were expensive and only installed on sports cars and race cars. The reason was pretty simple: to make the vehicle go faster. Today, turbochargers are still used on performance cars but they have become the technology of choice for standard passenger cars too. The reasoning in this case is that the auto manufacturers can install smaller motors in their cars when a turbocharger is used. This is advantageous because smaller motors pollute less and get better gas mileage.

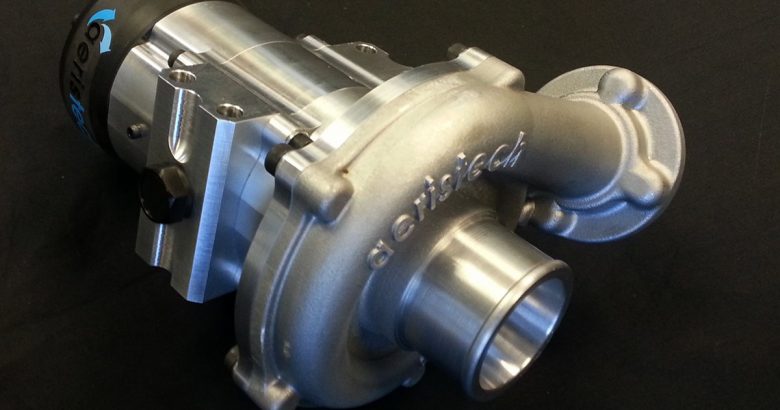

How standard turbochargers work

With help from the car experts at Savage L&B Chrysler of Robesonia, PA, a Dodge, Chrysler, Jeep, Ram dealer, we will explain how standard turbochargers work. Standard turbochargers use the powerful exhaust gases leaving an engine to power a small turbine that is used to drive outside air into the cylinders. Basically it uses exhaust gas to pressurize the air going into the engine. If you take a look inside one, it looks like a small fan with blades at either end. One end spins via the exhaust gases and the other end blows air into the engine.

Despite decades of constant improvements, all turbochargers suffer from something called “turbo-lag.” Turbo-lag is the delay in response that occurs when power is needed. Here’s the issue: when you punch the throttle of a turbocharged car, it takes a few seconds for the turbo to spool up and start working. This can be quite annoying when you need to accelerate quickly. Engineers have designed work-arounds, like twin-scroll and reduced mass turbochargers, but none of these make the problems go away completely. Bottom line, it’s hard to make a turbocharged engine deliver the immediate response of a naturally aspirated engine.

A solution: electric turbos

Instead of driving the turbo with exhaust gases, why not drive it with an electric motor? An electric motor can respond almost instantly (within 250 milliseconds) so there really isn’t any turbo lag. It seems like a perfect solution. The problem is that that this technology will be expensive at first. The electric motor to drive the turbo will have to be quite powerful and may need more than 12 volts to power it. This will require special alternators, batteries and wiring.

Who is doing it?

Most of the major automobile manufacturers are looking into electric turbo technology but few are broadcasting much information about their efforts yet. Audi, however, is close to putting a car with an electric turbocharger on the market. Their new SQ7 TDI sedan is slated to have an electric turbocharger installed on the engine. To drive it, a special 48-volt electrical sub-system is located in the trunk. The results are impressive: Audi says their sedan will have a 429-hp 4.0L V-8 diesel and can hit 62 MPH in 3.6 seconds. That’s one fast diesel.

The future of electric turbos

If the electric turbocharger concept works well, it should proliferate rapidly. It is unlikely to be seen on any economy cars anytime soon but we should see it becoming common on larger, luxury sedans.

Source: Savage L&B Chrysler of Robesonia, PA